Comprehensive PA Resin Series

Our polyamide compound resin lineup focuses on high-performance grades including PA610, PA612, PA1010, PA1012, and specialty types such as MXD6 and PA6I/6T. These resins are available with glass-fiber or mineral reinforcement to provide excellent dimensional stability, hydrolysis resistance, and mechanical strength. Low-moisture absorption in PA610/612 ensures minimal shrinkage and warpage in humid environments, while PA1010/1012 offer outstanding chemical resistance and UV durability for long-term outdoor use. All materials comply with IATF16949, ISO9001, and FDA food-contact standards, making them ideal for automotive, electronics, healthcare, and industrial applications.

| Item | Density | Tensile Strength | Melting Point | Water absorption | Application |

| (g/cm³) | (MPa) | (°C) | (%) | ||

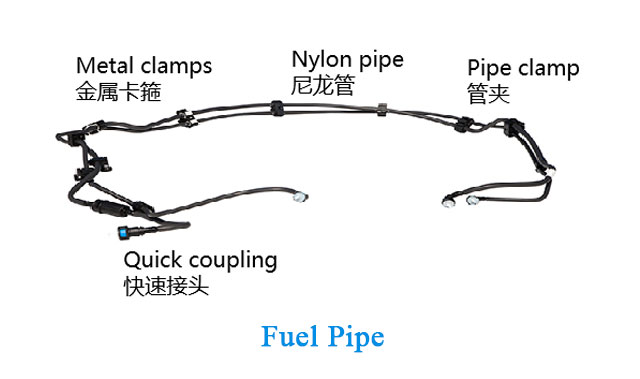

| PA12 | 1.02 | 50 | 178 | 1.6 | Automobile fuel pipe/Brake oil pipe/Hose/Cable coating/Electronic and electrical components/Sports shoe soles |

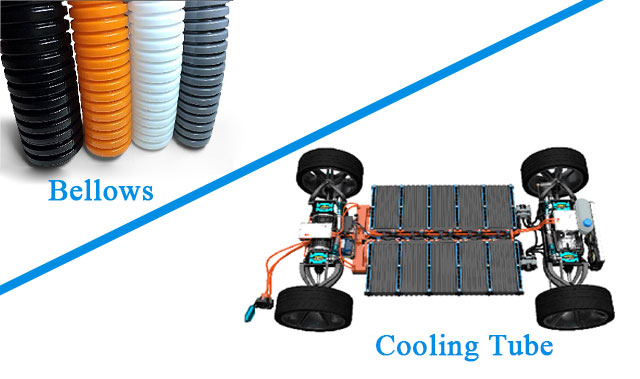

| PA612 | 1.07 | 62 | 210 | 3 | Cooling pipe/Bellows/Auto parts/Industrial brush wire/Sports equipment/Medical equipment |

| PA1012 | 1.04 | 60 | 192 | 2 | Cooling pipe/Oil pipeline/Gas pipe/Marine cable sheath/Brush wire |

| PA610 | 1.09 | 60 | 213 | 4 | Fuel pipe/Transmission pipeline/Brush wire/Fishing net/Fiber |

| PA1010 | 1.05 | 55 | 200~210 | 2.1 | Seal ring/Sliding bearing/Gear/Oil seal/Food machinery parts |

| PA6I6T | 1.18 | 92 | 260 | / | High temperature electrical connectors/Automotive electronics/LED packaging/Mobile phone parts |

| MXD6 | 1.21 | 97 | 240 | / | Auto parts/Electronic and electrical parts/Food packaging films |

Application

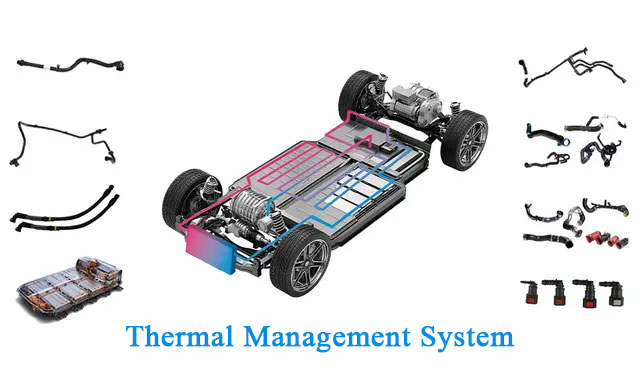

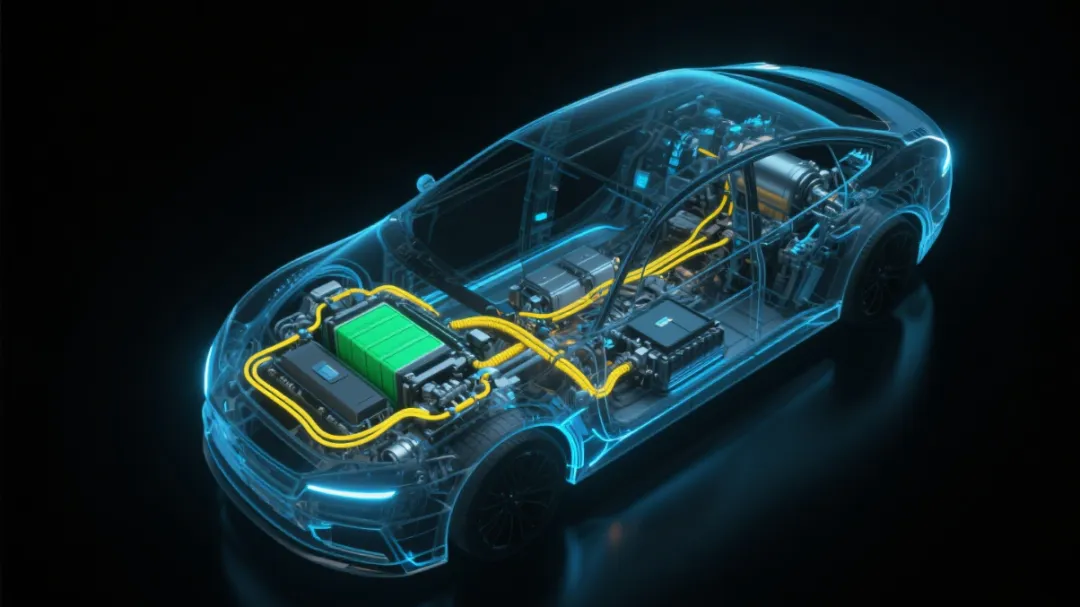

Orinko’s polyamide compound resins—including PA610, PA612, PA1010, PA1012, and PA6I/6T—are widely used across the automotive, electronics, energy, and industrial sectors.

New energy cooling pipe Single-wall tube

New energy cooling pipe Multi-wall tube

Flame retardant bellows for robots

Saline resistant chamber

Automotive fuel pipe

Air brake tube

Pipe joint

Pressure relief pipe

Sensor housing

Bus bar

Battery sealing ring

Blow molded nylon air intake pipe

Valve chamber cover

Oil pan/tank

Thermostat, pipe joints, and other hydrolysis-resistant components

Intercooler air intake pipe

Air intake manifold

Wear-resistant brush wire

Powder Coating for bowl basket/underwear button

Others

Product Advantages

Unmatched Material Performance

Our PA compounds deliver exceptional strength, thermal stability and chemical resistance for critical B2B applications.

High Mechanical Strength & Stiffness

Glass-fiber–reinforced PA610, PA612, PA1010, PA1012, and PA6I/6T compounds offer excellent mechanical strength and dimensional stability, even in high-humidity or chemically aggressive environments. With low moisture absorption and superior resistance to warping and hydrolysis, these resins maintain part integrity under thermal cycling and long-term load. Their precise moldability and stable shrinkage behavior make them ideal for precision components in automotive fluid systems, electronic housings, and outdoor applications requiring durability and performance consistency.

Superior Thermal & Chemical Resistance

Specialty PA610, PA612 and MXD6 resins offer continuous service temperatures up to 150 °C with minimal hydrolysis. Their low moisture absorption (< 0.5%) preserves mechanical properties in humid conditions. Resistant to fuels, oils, solvents and UV exposure, these compounds extend part life in fuel-system components, outdoor sporting goods and electronic enclosures, reducing maintenance and failure rates under aggressive chemical and environmental stress.

FAQs

Q1:What's your Product Range?

A1:PA6/PA66/PA610/PA612/PA1012/PA12/PA10T/HPA/PPA/PC/ABS/ASA/PMMA/PBT/PPS/HIPS/PET/TPE/TPV/TPEE/TPU/TPR/PPO/PPE/PP, plus PCR materials etc.Our products are widely applied to national mainstay industries and emerging industries like Home Appliances, Automobile, 5G, Electronic and Electrical, Medical, Rail Transit, Home Building Materials and Security.

Q2:Are there different grades of long-chain nylon available?

A2:Yes, there are various grades of long-chain nylon available, each designed for specific applications. Manufacturers offer a range of formulations with varying mechanical and thermal properties to suit different requirements.

Q3:What are the key characteristics of long-chain nylon?

A3:Long-chain nylon exhibits exceptional strength, durability, and abrasion resistance. It also possesses a high melting point, excellent chemical resistance, and low moisture absorption, making it suitable for a wide range of applications.

Q4:What melt temperature do your PA resins offer?

A4:Our PA6/66 grades melt at 220 °C–265 °C; PA610/612 at 230 °C–295 °C for high-temperature molding.

Related Blogs

-

Long Chain Nylon Resin Agent/Distributor Cooperation Program1. Project OverviewOur company focuses on the research and development and production of High-performance Polymer Materials. Our products are widely used in the fields of automobiles, electronics and electrical, industrial components and hiCompany News

Long Chain Nylon Resin Agent/Distributor Cooperation Program1. Project OverviewOur company focuses on the research and development and production of High-performance Polymer Materials. Our products are widely used in the fields of automobiles, electronics and electrical, industrial components and hiCompany News -

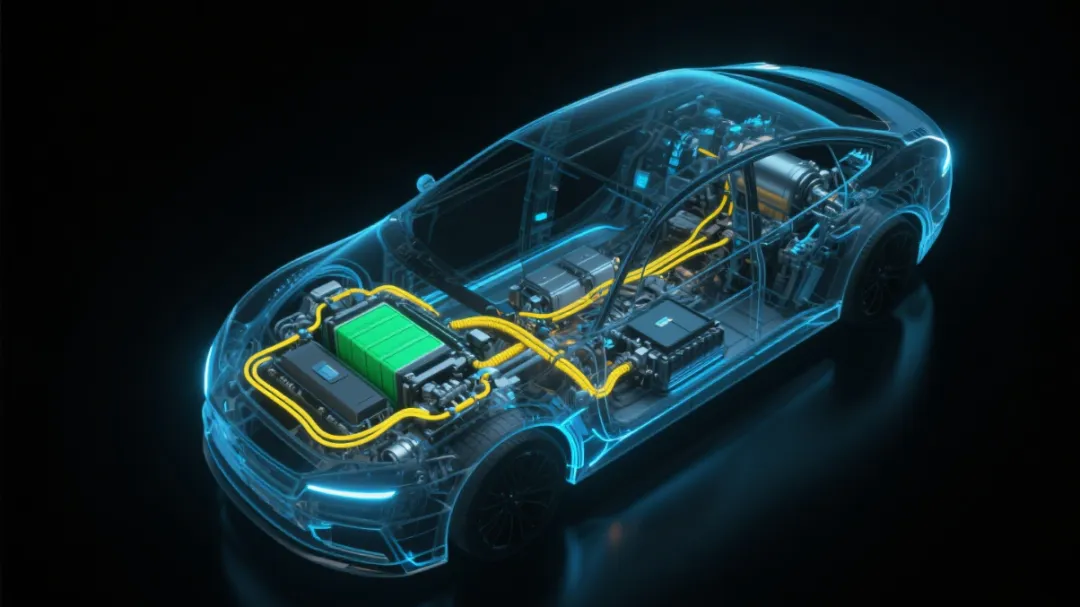

In the era of global automotive electrification, long-chain nylons such as PA612 and PA1012 are becoming essential materials for key components in new energy vehicles (NEVs), including cooling systems and hydrogen storage tanks. Their exceptional performance—including high temperature resistance, chCompany News

In the era of global automotive electrification, long-chain nylons such as PA612 and PA1012 are becoming essential materials for key components in new energy vehicles (NEVs), including cooling systems and hydrogen storage tanks. Their exceptional performance—including high temperature resistance, chCompany News -

Humanoid robots have stepped out of science fiction and into real life. Today, they serve as capable assistants in hospitals, warm companions in homes, and efficient workers on production lines. What makes these “intelligent new partners” so flexible and reliable? The answer lies in Orinko’s innovatCompany News

Humanoid robots have stepped out of science fiction and into real life. Today, they serve as capable assistants in hospitals, warm companions in homes, and efficient workers on production lines. What makes these “intelligent new partners” so flexible and reliable? The answer lies in Orinko’s innovatCompany News

Resin Demonstrations

Orinko Plastic, a leading PA compound manufacturer, delivers high-performance nylon resins for demanding industries. Watch our in-depth demos showcasing PA610’s low-moisture molding stability ,superior strength and stiffness in real-world injection molding and part testing.

PA610 Low-Moisture Molding Demo

This video highlights PA610 compound’s exceptional low water uptake and dimensional stability. See how the resin flows smoothly in precision injection molds at 260 °C, producing complex parts with minimal shrinkage (<0.5%) after humidity cycling. Ideal for connectors and sensor housings in humid environments.

PA66 Glass-Fiber Strength Test

Explore PA66 glass-fiber–reinforced compound’s high tensile strength and rigidity. The demo includes tensile bar molding at 265 °C, followed by mechanical testing showing >200 MPa tensile strength and 12 GPa flexural modulus. Perfect for structural automotive and industrial components requiring long-term load resistance.

Request Your Technical Quote

Need precise resin recommendations?

Our materials experts are ready to advise on grades, testing and logistics.

Mob

+86-13013179882