Product Description

Introduction to PA1010 Material

PA1010, also known as Nylon 1010 or Polyamide 1010, is a high-performance engineering plastic renowned for its exceptional mechanical properties, chemical resistance, and thermal stability. Developed independently in China, PA1010 is synthesized from castor oil, making it a sustainable and cost-effective choice for various industrial applications.

Key Characteristics of PA1010:

Excellent Mechanical Properties:

PA1010 exhibits high tensile strength, impact resistance, and toughness, making it suitable for load-bearing applications.

It demonstrates superior wear resistance and self-lubricating properties, reducing friction and extending the lifespan of components.

Low Water Absorption:

Good Chemical Resistance:

PA1010 resists corrosion from oils, solvents, and alkaline substances, making it ideal for applications in harsh chemical environments.

Thermal Stability:

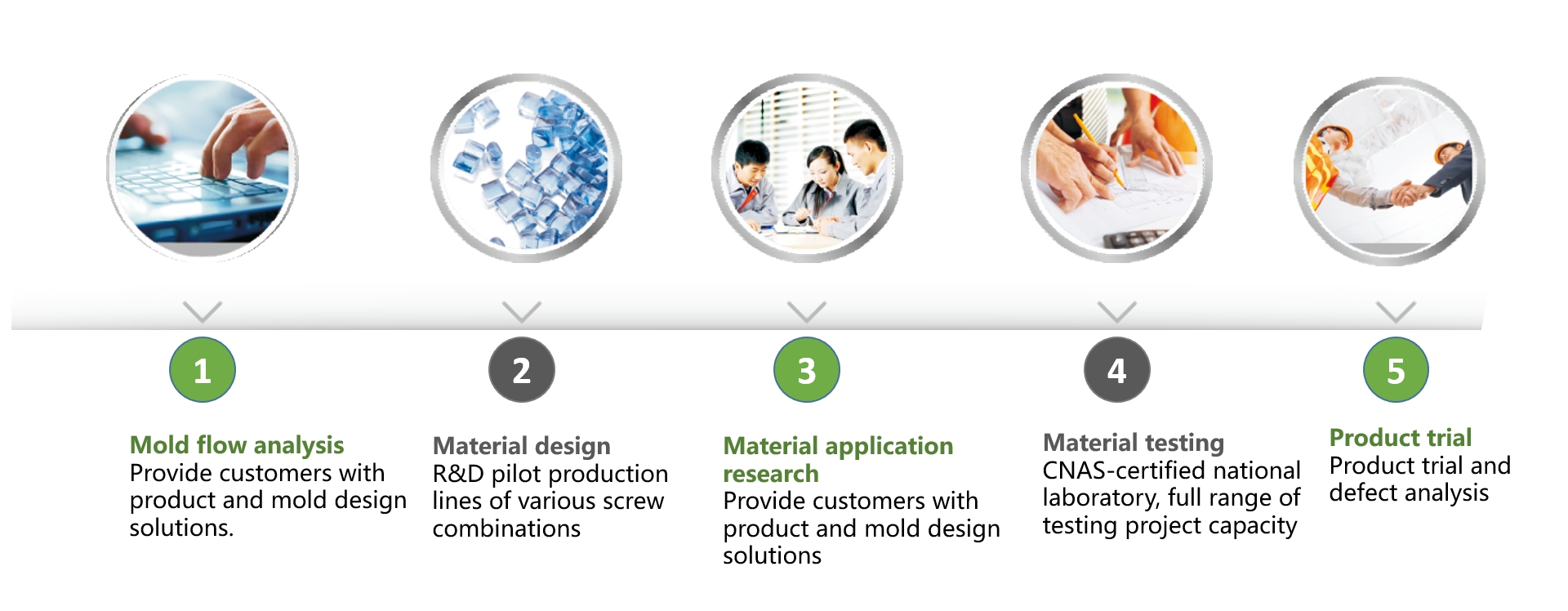

Easy Processability:

PA1010 offers excellent melt flow properties, facilitating easy processing through injection molding, extrusion, and blow molding techniques.

Application

The modified Nylon compound can be widely used in the automotive industry, machinery manufacturing(ol containers, textile machinery parts), and in the electronicindustry for making battrey casings, instrument rails, etc. It can also be used as bristles of toothbrushes, monoflaments and cablecorerings, etc.lt can be customized in injection and extrusion grade according to customers requirements.

Automotive

Battrey

Cable

Toothbrushe

Packaging & Shipping

Packing Details : Standard Packing(lnner /Aluminum Film ,Outer/Paper bag or woven bag).

Packaging Details:25kg/bag,or 750 kg/1000kg per jumbo bag

Delivery Details :T+10days

Port of departure:Wuhu, Shanghai,Ningbo,Guangzhou.

Company Information

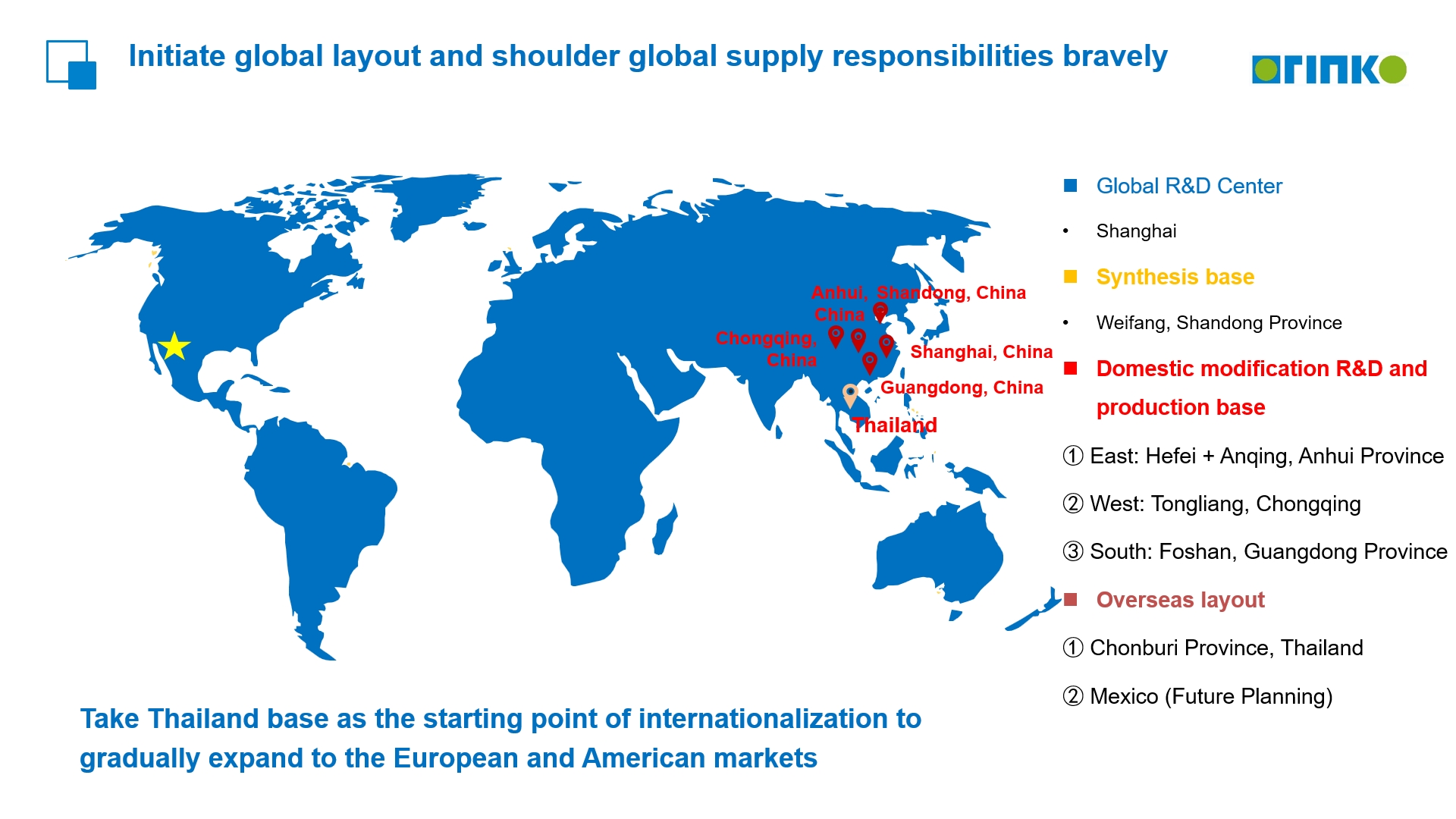

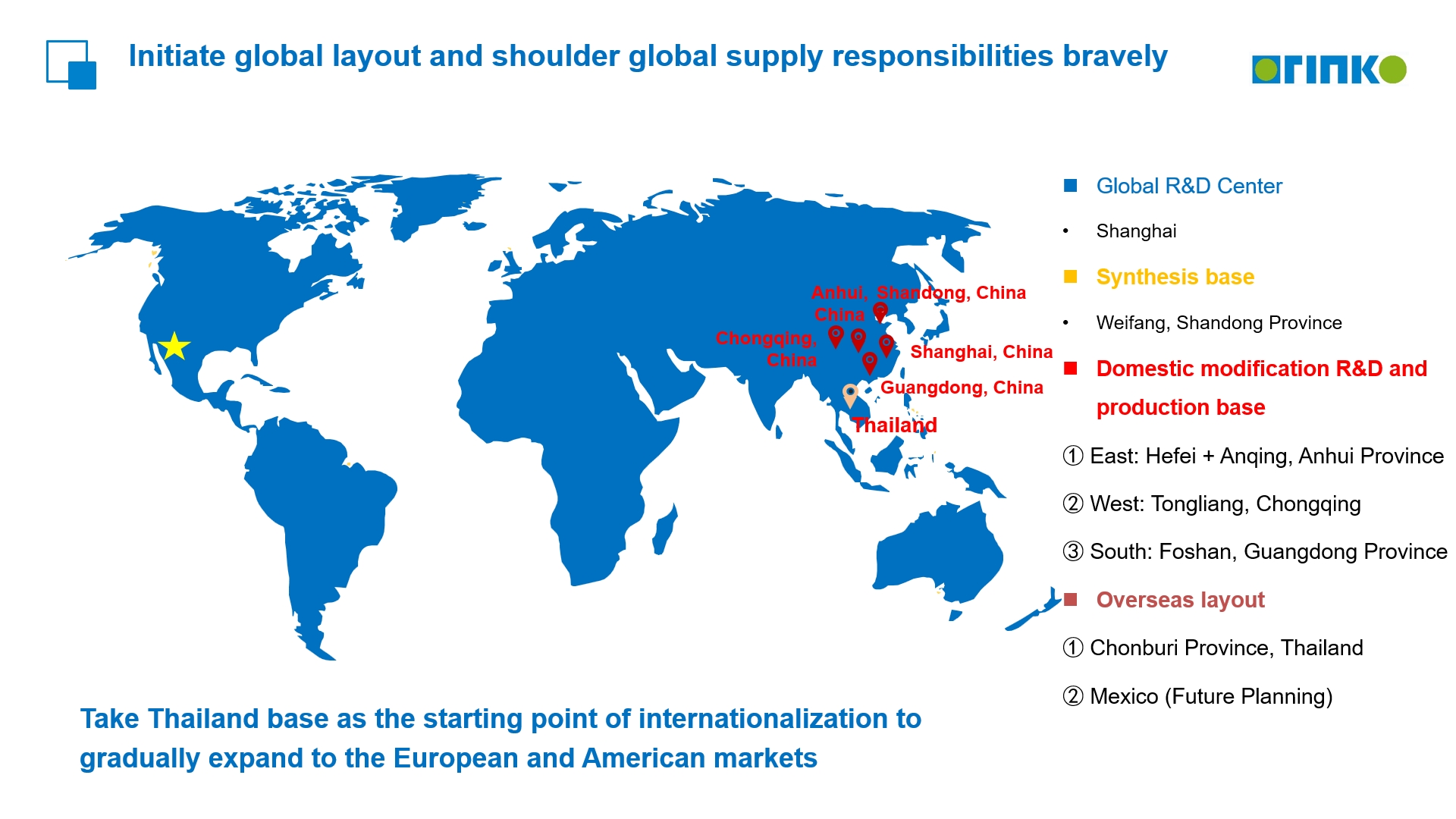

Orinko Plastics

We are one of the largest listed companies in China for polymer modified materials, including polyamides, polyolefins, polystyrene, and engineering plastics. We have collaborated with multiple automotive companies, such as Volkswagen, Ford, Toyota, Honda, Audi, etc

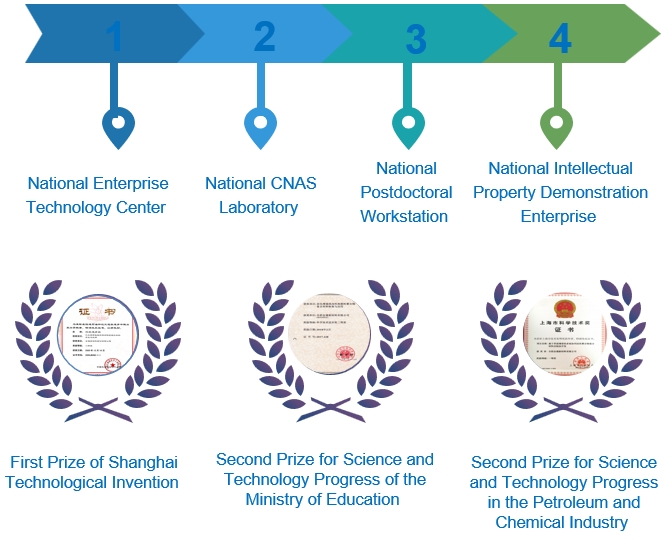

Certificate

ISO9001

ISO14001

ISO45001

IATF16949

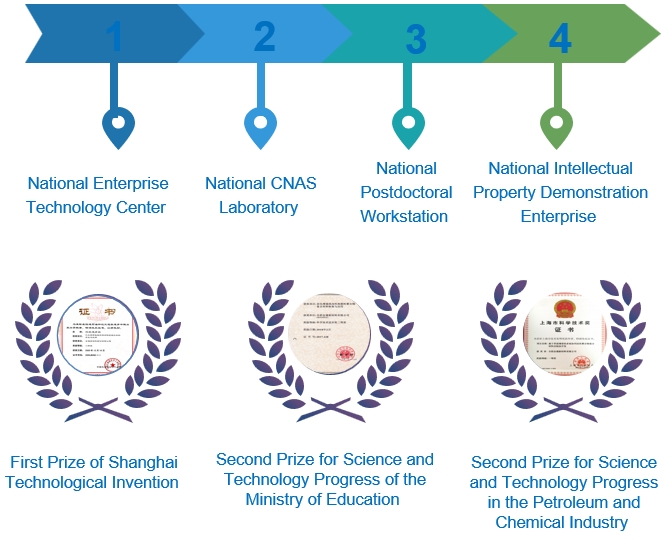

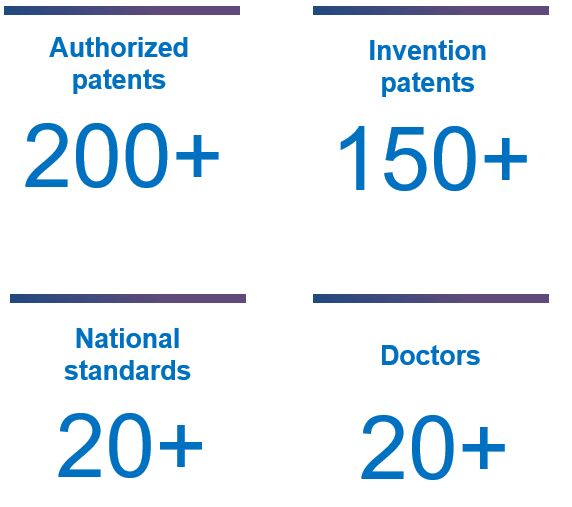

Inject impetus into the enterprise and industrial development with continuous innovation investment

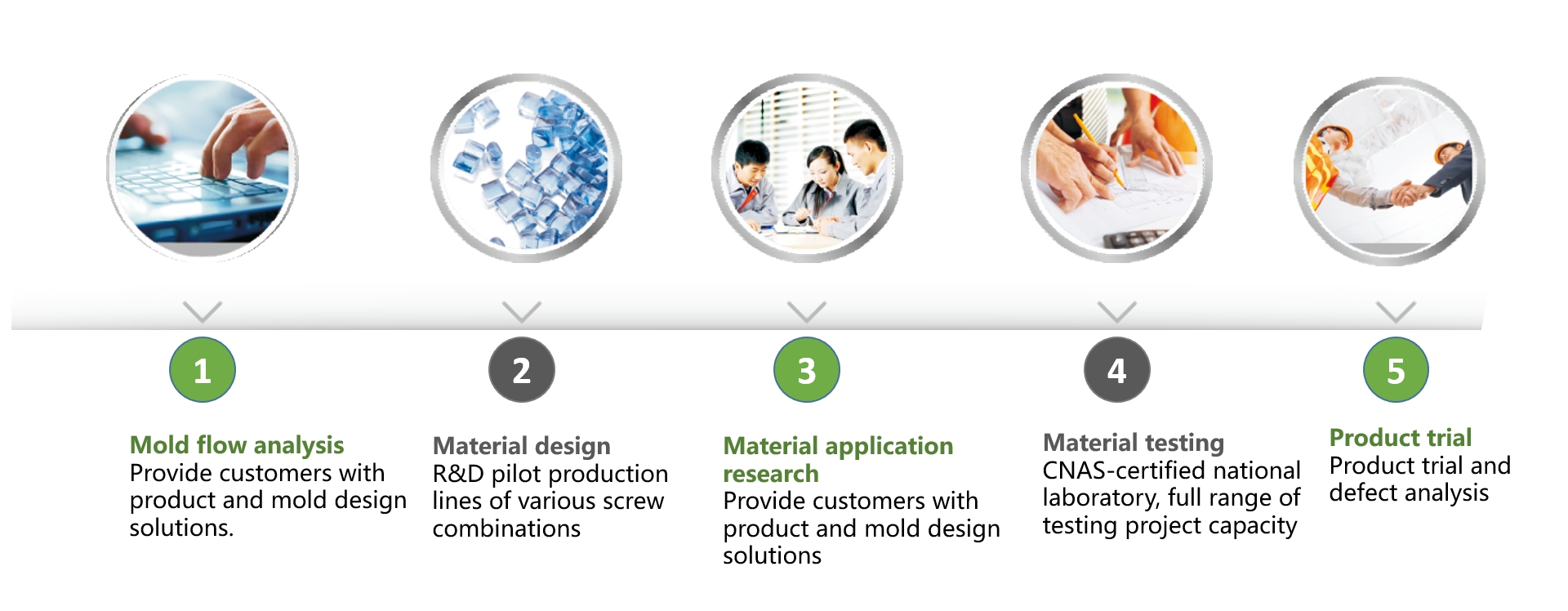

Innovation capability-provide overall solutions

Start from home appliances, serve many industry leaders and become their strategic partners