High‑Performance PA Compounds

Our PA Compound Lines

Key Properties:

Good toughness and impact resistance

Excellent wear resistance and self-lubricating properties

Cost-effective and easy to process

Higher water absorption, leading to lower dimensional stability compared to PA66

Automotive Applications:

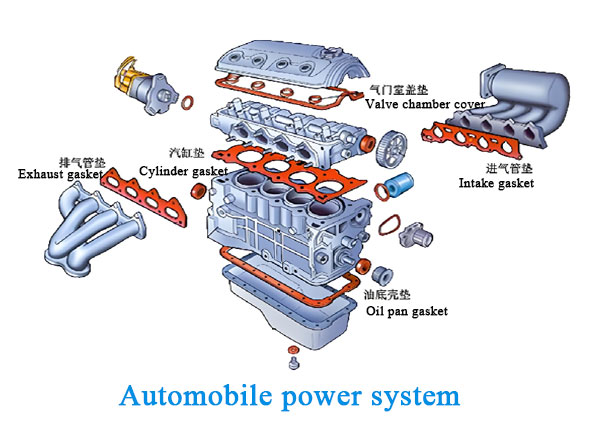

Fan blades, expansion tanks

Air filter housings

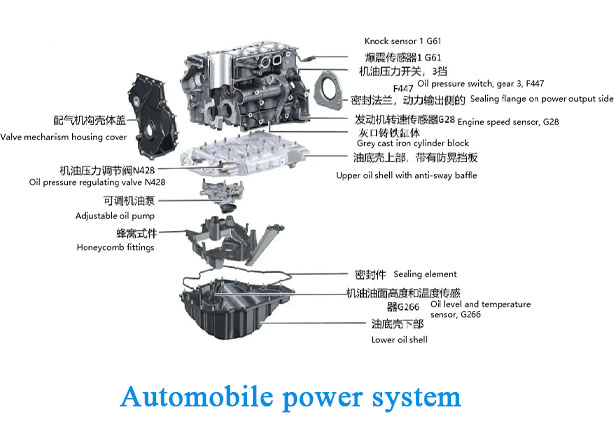

Oil pipes, engine covers, and other general-purpose structural parts

Key Properties:

Higher stiffness and thermal resistance than PA6

Superior wear resistance and chemical resistance

Higher melting point (~260°C)

Suitable for demanding high-temperature applications

Automotive Applications:

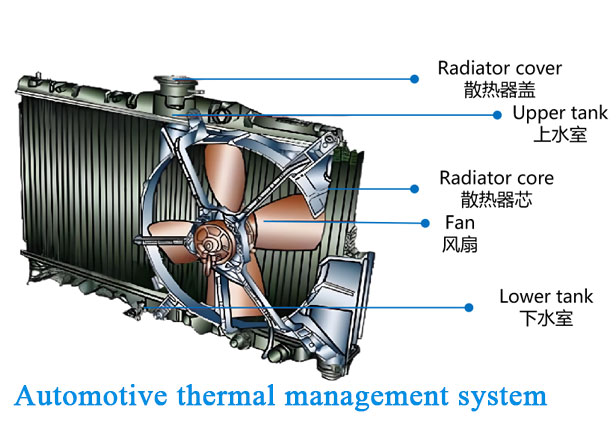

Radiator end tanks, water chambers

Fuel line connectors

Engine covers, turbocharger interfaces

Electrical connectors and plug housings

Key Properties:

Excellent heat resistance (continuous use up to 150~200°C+)

Very low water absorption and outstanding dimensional stability

High strength and rigidity, excellent creep resistance

Outstanding resistance to oils, fuels, and chemicals

Some grades offer natural flame retardancy (UL 94 V-0)

Automotive Applications

| Engine Components | Throttle bodies, intake manifolds, turbocharger housings – stable in high-temp, oil-rich environments |

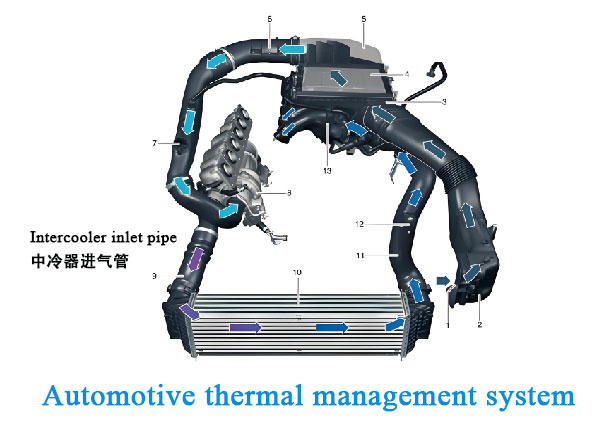

| Cooling System Parts | Water pump housings, thermostat valves – metal replacement for weight and cost savings |

| Electronic Systems | High-temp connectors, sensor housings |

| Lighting Systems | LED lamp bases, high-temp light brackets |

| New Energy Vehicles (NEVs) | Electrical module housings, battery frames, lightweight structural components |

Application

Product Advantage

Unmatched Mechanical Performance and Stability

Exceptional Strength & Stiffness

Our GF‑reinforced PA66 and PPA compounds achieve tensile strengths up to 200 MPa and flexural moduli over 12 GPa, ensuring load‑bearing capacity in structural components. The high fiber content suppresses creep and improves fatigue resistance, critical for under‑hood parts and industrial machinery. Precise molding reduces shrinkage and warpage, guaranteeing tight dimensional tolerances and minimal scrap rates.

Broad Thermal & Environmental Resistance

Orinko’s PPA and UV‑resistant PA1010/1012 grades maintain mechanical integrity at temperatures exceeding 180 °C and resist hydrolysis in humid conditions. Flame‑retardant UL94 V‑0 variants deliver reliable fire safety for electrical applications. Low‑moisture PA610/612 minimizes dimensional drift, making them ideal for outdoor and automotive sealing applications where stability and longevity are paramount.

Common Questions

Q1: What makes Orinko PA compounds unique?

A1: Orinko’s PA6/PA66/PPA compounds combine certified IATF 16949 quality, tailored glass‑fiber and flame‑retardant grades, and low‑moisture formulations for unmatched performance across industries.

Q2: Which PA grade for under‑hood applications?

A2: Choose glass‑fiber reinforced PA66 or PPA grades; they offer high strength, thermal stability up to 180 °C, and creep resistance required for engine components.

Q3: Can PA610/612 withstand humidity?

A3: Yes, low‑moisture PA610/612 resins exhibit minimal water absorption, ensuring dimensional stability and reliable sealing performance in humid or outdoor environments.

Q4: Are your compounds FDA compliant?

A4: Our standard PA6 and PA66 grades meet FDA food‑contact regulations, making them suitable for appliances and consumer products requiring direct food contact.

News & Events

-

PA612: The Powerhouse Material Revolutionizing IndustriesProduct DescriptionCompared with PA610, PA612 has lower density, better transparence, lower water absorption, higher dimension stability, better chemical resistance,and higher impact resistance.Typical ValueHB10HB30HB50ItemTest StandardUnitLow

PA612: The Powerhouse Material Revolutionizing IndustriesProduct DescriptionCompared with PA610, PA612 has lower density, better transparence, lower water absorption, higher dimension stability, better chemical resistance,and higher impact resistance.Typical ValueHB10HB30HB50ItemTest StandardUnitLow -

Discover the Allure of PA610: Revolutionary MaterialProduct DescriptionPA610 has good features of high strenath, good wear resistance, excelent oil resistance, low water absorption, high dimension stability,excellent electric properties and so on.Typical ValueHA10HA30HA50ItemTest StandardUnitLow vis

Discover the Allure of PA610: Revolutionary MaterialProduct DescriptionPA610 has good features of high strenath, good wear resistance, excelent oil resistance, low water absorption, high dimension stability,excellent electric properties and so on.Typical ValueHA10HA30HA50ItemTest StandardUnitLow vis -

The Unique Features and Applications of PA1012Product DescriptionPA6l/6T is an amorphous nylon resin which exhibits superior transparency, good barrier properties to gases, water, solvents and essentialoils and high temperature structural properties, which make it suitable for consideration in a num

The Unique Features and Applications of PA1012Product DescriptionPA6l/6T is an amorphous nylon resin which exhibits superior transparency, good barrier properties to gases, water, solvents and essentialoils and high temperature structural properties, which make it suitable for consideration in a num

Contact Us

Have questions about our PA compounds? Our experts are ready to assist with product selection, technical support, or custom formulations.

Reach out today!

Mob

+86-512-6670-6407