Product Deacription

Modification of PA1012:

To further enhance the properties of PA1012 or tailor it to specific applications, various modification techniques are employed:

Glass Fiber Reinforcement: Adding glass fibers to PA1012 significantly improves its mechanical strength, stiffness, and heat deflection temperature, making it suitable for load-bearing components.

Impact Modifiers: Incorporating impact modifiers, such as elastomers or rubber particles, enhances the toughness of PA1012, making it more resistant to impact and fatigue.

Flame Retardants: For applications requiring flame resistance, flame retardant additives are introduced to PA1012 to meet specific safety standards.

Lubricants and Wear Additives: To improve wear resistance and reduce friction, lubricants or wear-resistant additives are often blended with PA1012.

UV Stabilizers: For outdoor applications, UV stabilizers are added to protect the material from degradation caused by ultraviolet radiation.

Application

Modified PA1012 materials find extensive use in various industries due to their enhanced properties:

Automotive Industry: Used in fuel lines, brake systems, and other components requiring high toughness, chemical resistance, and dimensional stability.

Electrical and Electronics: Suitable for connectors, switches, and other electrical components due to its good electrical insulation properties and flame retardancy.

Industrial Machinery: Employed in gears, bearings, and other mechanical parts that require high wear resistance and load-bearing capacity.

Consumer Goods: Used in the production of durable consumer products, such as sports equipment, household appliances, and toys.

Automotive

Battrey

Cable

Toothbrushe

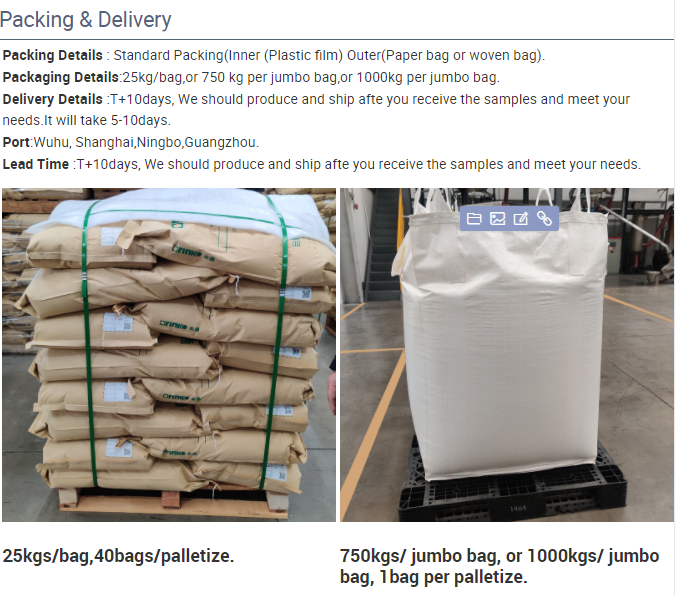

Packaging & Shipping

Our Services