Product Description

ORINKO Polyamide 612 (PA612) is a long-chain nylon, which is made by condensation polymerization of ethylenediamine and dodecanedioic acid as raw materials. The raw material dodecanedioic acid can be produced through chemical synthesis or microbial fermentation. ORINKO integrates PA612 forward and backward, with our own factories in backward raw material production, forward resin polymerization and polyamide compound.

Depending on formulation and viscosity, ORINKO Polyamide PA612 can be processed using a range of different methods, such as injection molding, tube extrusion, film extrusion or blow molding. By using additives, fillers, pigments, plasticizers, modifiers or processing aids. ORINKO can precisely adjust Polyamide to customer requirements and specific applications.

ORINKO Polyamide PA612 resin has a series of excellent properties, such as:

Very low water absorption and excellent dimensional stability

Very good chemical and weather resistance

Excellent hydrolysis resistance

Lower molding shrinkage

Excellent mouldability

High melting point: 215℃

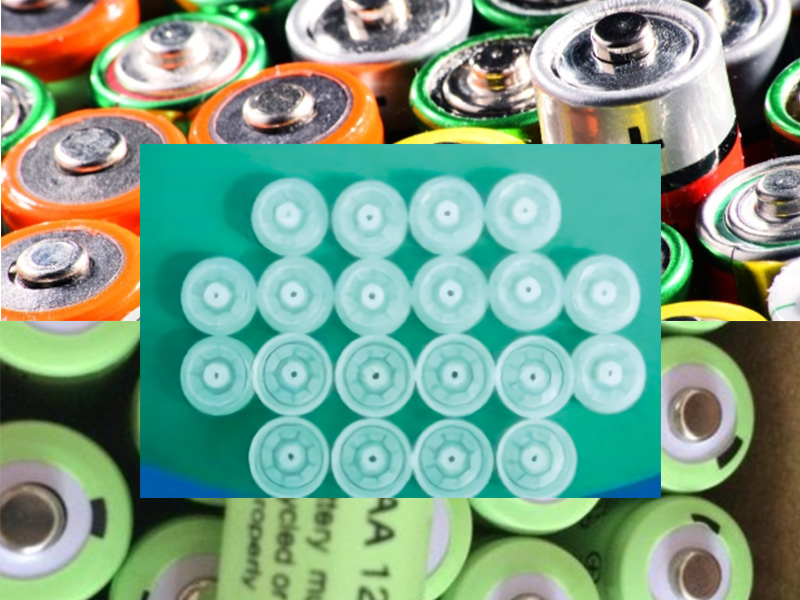

Application

The modified PA612 can be widely used in the automotive industry, machinery manufacturing(ol containers, textile machinery parts), and in the electronicindustry for making battrey casings, instrument rails, etc. It can also be used as bristles of toothbrushes, monoflaments and cablecorerings, etc.lt can be customized in injection and extrusion grade according to customers requirements.

Automotive

Battrey

Cable

Toothbrushe

Packaging & Shipping